With the advancement of technology and the enhancement of environmental awareness, LED outdoor lighting, as an efficient, energy-saving and long-life lighting solution, has been wi...

READ MOREWholesale GU10 Aluminum Ceiling Light Series

GU10 Aluminum Ceiling Light Series Manufacturers

About Us

Ningbo Hongrui Lighting Technology Co., Ltd.

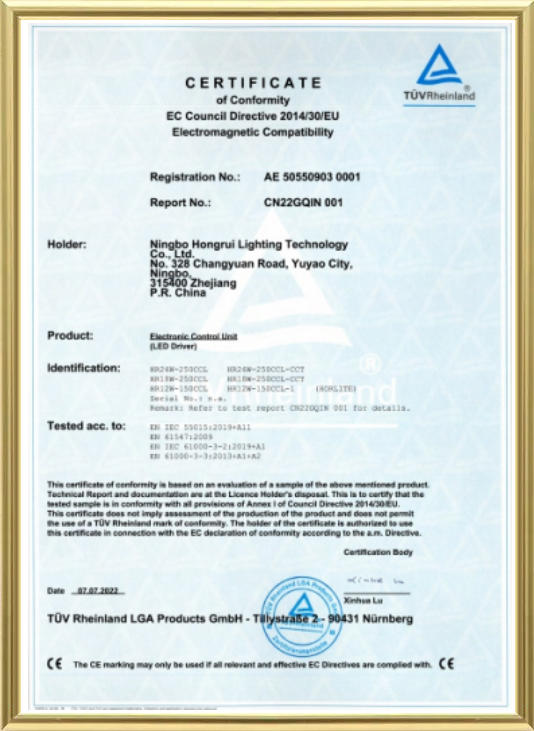

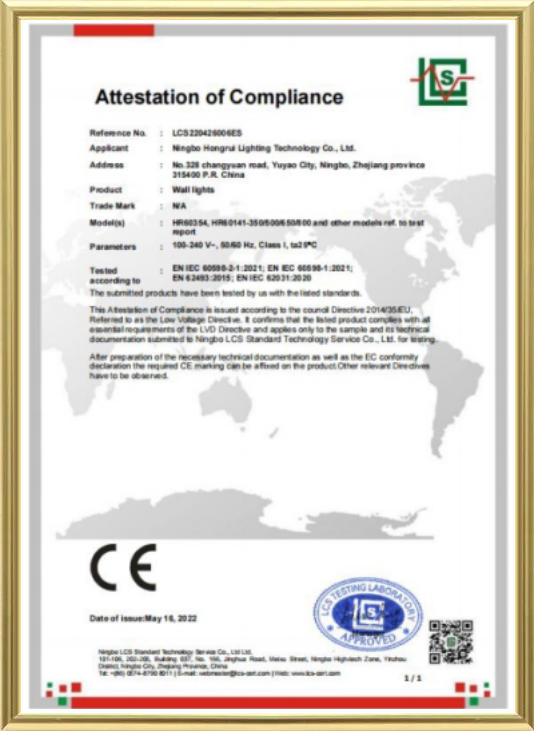

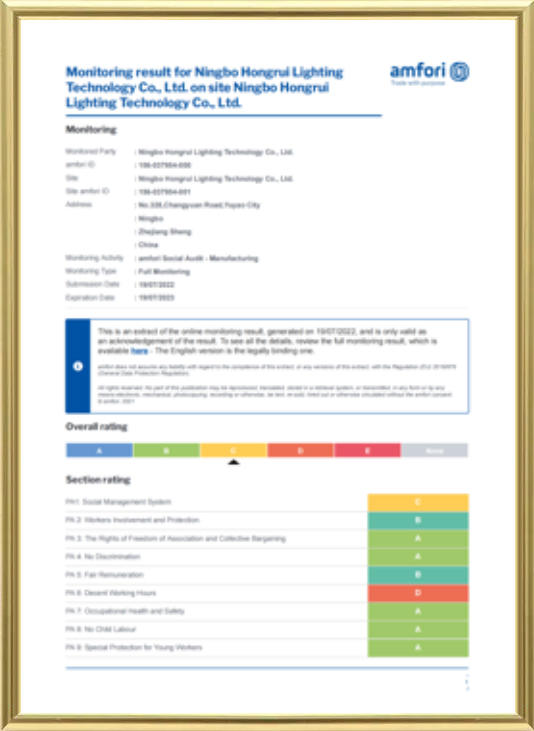

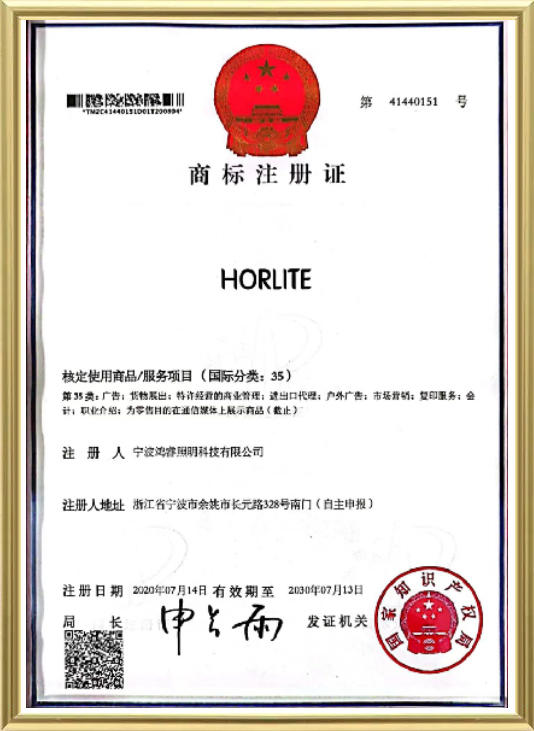

Ningbo Hongrui Lighting Technology Co., Ltd. was founded in 2014, is a China GU10 Aluminum Ceiling Light Series Manufacturers and GU10 Aluminum Ceiling Light Series Factory, , involved in the types of products: wall lamps, garden lights, ceiling lights, pendant lights, underground lamps, mirror headlights, E26 lamp holders, wires and ect. Products are widely used in domestic and foreign commercial lighting field. In addition, our company's systems and products have passed UL, CE, RoHS, GS, 7P certification.

Because we have perfect software and hardware support as follows:

1. Our hardware support: advanced precision mold processing capabilities, production equipment, testing equipment, etc.

2.Our software support: highly qualified innovative professional technical team and sales management team. All production processes of the company adopt advanced ERP data control system, forming the core competitiveness of "quality first, focus on talent, efficient service". In particular, it has become a well-known "domestic headlamp industry supporting supplier" cooperation.

Because we have perfect software and hardware support as follows:

1. Our hardware support: advanced precision mold processing capabilities, production equipment, testing equipment, etc.

2.Our software support: highly qualified innovative professional technical team and sales management team. All production processes of the company adopt advanced ERP data control system, forming the core competitiveness of "quality first, focus on talent, efficient service". In particular, it has become a well-known "domestic headlamp industry supporting supplier" cooperation.

News

-

-

With the accelerating urbanization process, LED outdoor lights, as an important part of modern urban night scenes, have been widely used for their high efficiency, long life and en...

READ MORE -

The environmental protection role of LED outdoor lights in urban lighting is gradually penetrating into every corner of our lives in a gentle and firm way. These modern lighting eq...

READ MORE -

The huge potential and far-reaching impact of LED outdoor lights in the field of energy saving and emission reductionIn the context of today's increasingly severe global energy cri...

READ MORE

Message Feedback

GU10 Aluminum Ceiling Light Series Industry knowledge

Are there any advantages of aluminum as a material for ceiling lights in terms of heat dissipation?

Aluminum is often preferred for ceiling lights and other electronic components due to its excellent heat dissipation properties. Here are some advantages of using aluminum for heat dissipation in ceiling lights:

High Thermal Conductivity: Aluminum has a high thermal conductivity, which means it can efficiently transfer heat away from the source. This property helps in distributing heat evenly across the surface, preventing localized hotspots.

Lightweight: Aluminum is a lightweight material, making it easier to handle and install. This is particularly advantageous in ceiling lights where weight considerations are important.

Corrosion Resistance: Aluminum has natural corrosion resistance, which is crucial for ensuring the long-term durability of ceiling lights, especially in environments with high humidity or exposure to outdoor elements.

Cost-Effectiveness: Aluminum is relatively inexpensive compared to some other materials with similar heat dissipation properties. This makes it a cost-effective choice for manufacturers of lighting fixtures.

Machinability: Aluminum is easy to machine and shape, allowing for the creation of intricate designs and efficient heat sink structures. This versatility is beneficial for designing effective heat dissipation solutions.

Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice. The ability to recycle aluminum reduces the environmental impact and energy consumption associated with manufacturing new materials.

Aesthetic Options: Aluminum can be anodized or coated with various finishes, providing designers with aesthetic options to match the overall look and feel of the ceiling lights.

When designing ceiling lights, efficient heat dissipation is crucial to ensure the longevity and optimal performance of the lighting fixtures. The use of aluminum helps address these thermal management requirements effectively.

Does the design of the Aluminum Ceiling Lights contribute to efficient heat management?

The design of aluminum ceiling lights can contribute to efficient heat management to some extent. Aluminum is known for its excellent thermal conductivity, which means it can transfer heat effectively. When used in the design of ceiling lights, aluminum can help dissipate heat generated by the light source, such as LED bulbs or other lighting technologies.

Efficient heat management is crucial for the longevity and performance of lighting fixtures, especially those with high-intensity light sources. If heat is not effectively dissipated, it can lead to reduced lifespan, color degradation, and decreased overall efficiency of the light.

In the design of aluminum ceiling lights, engineers may incorporate features such as heat sinks, fins, or other heat-dissipating structures to enhance thermal performance. These elements help in conducting and radiating heat away from the light source, preventing the fixture from overheating.

It's essential to note that the overall efficiency of heat management depends on various factors, including the specific design of the light fixture, the type and wattage of the light source, and the environmental conditions in which the light operates. Therefore, while aluminum can be a beneficial material for heat management, the overall design and engineering of the ceiling light play a crucial role in ensuring efficient heat dissipation.

Aluminum is often preferred for ceiling lights and other electronic components due to its excellent heat dissipation properties. Here are some advantages of using aluminum for heat dissipation in ceiling lights:

High Thermal Conductivity: Aluminum has a high thermal conductivity, which means it can efficiently transfer heat away from the source. This property helps in distributing heat evenly across the surface, preventing localized hotspots.

Lightweight: Aluminum is a lightweight material, making it easier to handle and install. This is particularly advantageous in ceiling lights where weight considerations are important.

Corrosion Resistance: Aluminum has natural corrosion resistance, which is crucial for ensuring the long-term durability of ceiling lights, especially in environments with high humidity or exposure to outdoor elements.

Cost-Effectiveness: Aluminum is relatively inexpensive compared to some other materials with similar heat dissipation properties. This makes it a cost-effective choice for manufacturers of lighting fixtures.

Machinability: Aluminum is easy to machine and shape, allowing for the creation of intricate designs and efficient heat sink structures. This versatility is beneficial for designing effective heat dissipation solutions.

Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice. The ability to recycle aluminum reduces the environmental impact and energy consumption associated with manufacturing new materials.

Aesthetic Options: Aluminum can be anodized or coated with various finishes, providing designers with aesthetic options to match the overall look and feel of the ceiling lights.

When designing ceiling lights, efficient heat dissipation is crucial to ensure the longevity and optimal performance of the lighting fixtures. The use of aluminum helps address these thermal management requirements effectively.

Does the design of the Aluminum Ceiling Lights contribute to efficient heat management?

The design of aluminum ceiling lights can contribute to efficient heat management to some extent. Aluminum is known for its excellent thermal conductivity, which means it can transfer heat effectively. When used in the design of ceiling lights, aluminum can help dissipate heat generated by the light source, such as LED bulbs or other lighting technologies.

Efficient heat management is crucial for the longevity and performance of lighting fixtures, especially those with high-intensity light sources. If heat is not effectively dissipated, it can lead to reduced lifespan, color degradation, and decreased overall efficiency of the light.

In the design of aluminum ceiling lights, engineers may incorporate features such as heat sinks, fins, or other heat-dissipating structures to enhance thermal performance. These elements help in conducting and radiating heat away from the light source, preventing the fixture from overheating.

It's essential to note that the overall efficiency of heat management depends on various factors, including the specific design of the light fixture, the type and wattage of the light source, and the environmental conditions in which the light operates. Therefore, while aluminum can be a beneficial material for heat management, the overall design and engineering of the ceiling light play a crucial role in ensuring efficient heat dissipation.

Copyright © Ningbo Hongrui Lighting Technology Co., Ltd. All Rights Reserved. Wholesale GU10 Aluminum Ceiling Light Series Manufacturers

简体中文

简体中文 English

English